What Is Epoxy Used For In Construction?

Epoxy has become a fundamental material in construction due to its versatility and reliability. Whether you are constructing a new building or working on a renovation project, epoxy plays a key role in enhancing the performance, durability, and overall functionality of structures. From adhesives to coatings, epoxy resin has a broad range of applications in the construction industry. In this article, we will explore the various applications of epoxy in construction, highlighting its multiple roles and benefits in construction projects.

Epoxy is a thermoset polymer that starts as a liquid resin and, when mixed with a hardener, transforms into a solid plastic material. This chemical reaction produces an incredibly strong bond, making it a preferred choice for various construction applications. The exceptional bonding properties, resistance to moisture and chemicals, and durability make epoxy invaluable for projects where longevity and strength are paramount.

Epoxy Adhesives and Structural Bonding

One of the most well-known uses of epoxy in construction is as an adhesive. Epoxy adhesives are essential for creating strong, long-lasting bonds between different materials. These adhesives are especially useful in situations where other types of adhesives might fail, such as in bonding metals, concrete, glass, and wood.

Epoxy adhesives are widely used in structural bonding for building components. Whether attaching panels, frames, or other structural elements, epoxy adhesives deliver exceptional strength and stability. In high-stress areas, such as the foundation of a building or bridges, the ability of epoxy to resist stress, moisture, and temperature fluctuations is crucial to maintaining the structure’s integrity.

Epoxy adhesives are also commonly used in the construction of laminated wood for decks, roofs, and walls. These adhesives provide a durable bond that ensures the structural integrity of the wood over time, even in challenging environmental conditions.

Flooring Applications: Epoxy Resin as a Durable Coating

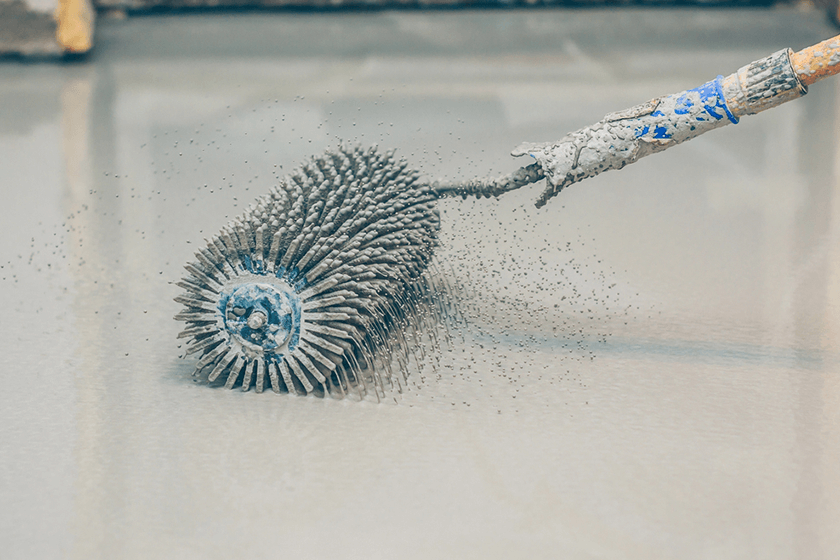

Epoxy is frequently used as a floor coating in both residential and industrial buildings. This type of resin creates a tough, durable surface that resists wear, moisture, and chemicals, making it ideal for environments that experience heavy foot traffic, machinery, or harsh weather conditions.

Epoxy floor coatings are especially useful in commercial and industrial settings, such as warehouses, factories, and hospitals, where floors are subjected to extreme conditions. These coatings provide a seamless, high-gloss finish that is easy to clean and maintain. With the ability to resist stains, scratches, and impacts, epoxy flooring ensures long-lasting durability even in high-use environments.

Beyond durability, epoxy flooring also offers aesthetic benefits. Customizable options, such as adding colored chips or aggregates, allow for a variety of decorative effects. Epoxy can be used for terrazzo floors, chip flooring, or even floors with anti-slip additives for added safety.

For homebuilders and renovators, epoxy flooring is an excellent choice for garages, basements, or kitchens, where the floor is exposed to moisture or chemicals. The durability and resistance of epoxy make it an ideal material for floors that require withstanding the rigors of everyday use.

Water-Resistant and Chemical-Resistant Coatings

Epoxy coatings are also highly regarded for their resistance to water and chemicals. This makes them essential for use in areas where exposure to moisture or chemicals could cause damage to traditional building materials.

For instance, epoxy is often applied to concrete floors in basements, parking garages, and warehouses to protect them from water penetration. In these environments, water can weaken the structure over time, leading to cracks, mold, and corrosion. Epoxy coatings create a strong, impermeable layer that prevents water from seeping into the surface, helping to maintain the integrity of the foundation.

Chemical resistance is another crucial property of epoxy coatings. In industrial and commercial environments, floors, walls, and countertops are often exposed to a range of chemicals. Epoxy coatings can be formulated to resist chemicals such as oils, solvents, acids, and alkalis, thereby preventing damage to surfaces and ensuring long-term performance.

In the marine industry, epoxy is commonly used for protecting boat hulls, decks, and other surfaces exposed to seawater. The epoxy forms a protective barrier against the harsh marine environment, safeguarding the materials from corrosion, saltwater damage, and the wear and tear caused by constant exposure to water.

Concrete and Structural Repairs

Epoxy is widely used for repairs in concrete construction. It can be used to fill cracks, voids, and other imperfections in concrete surfaces, thereby restoring the material’s strength and integrity. Epoxy resins are especially effective at bonding with concrete, creating a seamless repair that restores both functionality and appearance.

One of the key advantages of epoxy in concrete repair is its fast-curing nature. When combined with the appropriate hardener, epoxy can set within hours, allowing for a quick turnaround on repair projects. This is especially useful in commercial and industrial settings, where downtime must be minimized to prevent disruptions to operations.

Epoxy is also used in structural strengthening. When combined with carbon fiber or other reinforcement materials, epoxy creates a strong, flexible bond that can be used to reinforce beams, columns, and other load-bearing structures. This makes it ideal for retrofitting older buildings or adding additional support to structures under renovation or repair.

Epoxy Resin for Resin Countertops and Surface Coatings

Another growing trend in construction and design is the use of epoxy resin for creating countertops and surface coatings. Epoxy resins are used in the fabrication of custom countertops, including those made from recycled glass or other composite materials. These countertops are not only durable and long-lasting but also highly customizable.

Resin countertops made from epoxy are available in a wide range of colors and patterns. Builders and designers can create unique, one-of-a-kind surfaces by adding pigments, metal flakes, or even small objects into the resin. This enables the creation of countertops with a high level of aesthetic appeal, making them a popular choice in both residential and commercial settings.

The durability of epoxy countertops is unmatched. They resist scratches, stains, and heat, making them ideal for use in kitchens, bathrooms, and other high-traffic areas. Epoxy resin also offers excellent adhesion to various materials, enabling a seamless bond between the countertop and its supporting base.

Epoxy Resin for Environmental Sustainability

In recent years, epoxy has found applications in environmentally sustainable construction projects. Epoxy resins can be blended with recycled materials to create composite surfaces, such as countertops and flooring, that help builders achieve green building certifications, like LEED (Leadership in Energy and Environmental Design).

Epoxy’s ability to bond with a variety of materials, including recycled glass, makes it an attractive option for sustainable construction. By using post-consumer waste products in the creation of surfaces, builders can contribute to reducing the demand for new raw materials and help conserve resources.

This shift toward more sustainable materials is part of the construction industry’s broader move toward green building practices. The versatility and durability of epoxy resin align with the growing demand for products that are both eco-friendly and high-performing.

Why Epoxy is a Must-Have in Construction

The widespread use of epoxy resin in construction can be attributed to its unique properties and versatility. From providing strong adhesion in structural bonding to enhancing the durability of floors and countertops, epoxy resin plays a pivotal role in improving the quality and longevity of construction projects. Its resistance to moisture, chemicals, and high temperatures makes it a reliable material in environments that are subjected to harsh conditions.

Moreover, epoxy’s adaptability means it can be used in a wide range of construction applications. Whether you need to create a seamless floor, repair concrete, or bond various materials, epoxy resin offers an effective solution for achieving durable, long-lasting results.

Epoxy for Outdoor Coatings and Sealants

In construction, maintaining the longevity and appearance of outdoor surfaces is a constant challenge. Epoxy resins offer a practical solution to this issue, providing strong, protective coatings and sealants for outdoor structures. From concrete floors to metal fences, epoxy coatings safeguard materials from the harsh effects of weather, wear, and chemical exposure.

One of the most significant advantages of using epoxy for outdoor applications is its resistance to the elements. Epoxy coatings form a durable, impermeable layer that protects surfaces from rain, UV rays, extreme temperatures, and even pollutants. For instance, in concrete applications, epoxy coatings protect surfaces from water infiltration, which can lead to the deterioration of the material over time. Whether applied to driveways, patios, or exterior walls, epoxy ensures that outdoor surfaces remain intact and functional for years.

Epoxy is also commonly used in marine construction. The harsh marine environment, with constant exposure to water, salt, and UV radiation, requires materials that can withstand these conditions. Epoxy coatings are frequently used to protect boat hulls, docks, and other marine structures, providing a durable barrier against corrosion and saltwater damage. This use of epoxy in marine construction is especially important as it prolongs the life of the structure and reduces maintenance costs over time.

Epoxy Resin for Bridges and Infrastructure

Epoxy resin also plays a critical role in the construction of bridges and other infrastructure. In these large-scale projects, structural integrity is paramount, and epoxy’s strength and durability make it an invaluable material. Epoxy is often used in the reinforcement and repair of bridges, tunnels, and highways. When combined with reinforcement materials like carbon fiber or glass fibers, epoxy resins can increase the load-bearing capacity of the structure without adding unnecessary weight.

For existing infrastructure, epoxy can be used to repair cracks and joints, thereby preventing further damage and extending the lifespan of the structure. These repairs can be completed quickly and with minimal disruption, making epoxy a go-to material for maintenance teams working on vital infrastructure. In some cases, epoxy resin is even used in the construction of new bridge components, such as decks or supports, where it helps to reduce weight while maintaining the necessary strength and performance.

Moreover, epoxy resins’ resistance to environmental factors such as chemical exposure, moisture, and extreme temperatures makes them an ideal choice for infrastructure exposed to the elements. Whether in tunnels, bridges, or roadways, epoxy ensures that these structures remain safe and operational, even in the face of challenging conditions.

Epoxy in Insulation and Soundproofing

Epoxy’s application in construction goes beyond surface coatings and structural bonding. In recent years, epoxy resins have been incorporated into the development of insulation materials and soundproofing systems. Due to their ability to form airtight seals and create strong bonds with various materials, epoxy resins are ideal for insulation purposes.

In the construction of energy-efficient buildings, epoxy is used to enhance the thermal insulation properties of walls, floors, and ceilings. Epoxy-based materials can prevent heat loss, ensuring that energy is used efficiently. This is especially important in the construction of commercial buildings, where heating and cooling costs can be significant. By incorporating epoxy-based insulation materials, construction teams can help reduce energy consumption and lower operational costs.

Epoxy is also used in soundproofing applications. In buildings, particularly in commercial spaces or multi-unit residences, reducing noise pollution is a critical consideration. Epoxy resins are used to create soundproof barriers that effectively absorb and block sound waves, ensuring a quieter and more comfortable environment. These soundproofing systems are ideal for concert halls, theaters, offices, and apartments where noise control is necessary.

Environmental Impact of Epoxy Resin in Construction

As the construction industry shifts toward more sustainable practices, the use of epoxy resin is being reevaluated for its environmental impact. While epoxy resins are known for their durability and strength, they are also being formulated to be more eco-friendly. Manufacturers are now producing bio-based epoxy resins, which are derived from renewable resources rather than petroleum-based materials. These bio-based resins offer the same high-performance characteristics of traditional epoxy, with the added benefit of a smaller carbon footprint.

Additionally, epoxy is being used in recycling programs within the construction industry. For example, epoxy resins can be combined with recycled materials, such as glass or plastic, to create composite materials used for flooring or countertops. This innovation reduces reliance on virgin materials, further contributing to the industry’s sustainability efforts.

Furthermore, epoxy’s durability means that fewer materials need to be replaced over time, resulting in reduced waste in the long run. In construction, where materials often need to be replaced due to wear and tear, epoxy’s long-lasting properties help reduce the frequency of repairs or replacements, thus minimizing the environmental impact of constant construction activity.

Epoxy for Mold and Mildew Resistance

Epoxy resins are also increasingly used to prevent the growth of mold and mildew in construction projects. These fungi can thrive in damp environments, causing damage to building materials and leading to expensive repairs and potential health risks. Epoxy coatings and adhesives create an impermeable layer that prevents moisture from infiltrating surfaces, thereby reducing the conditions necessary for mold and mildew growth.

In areas such as basements, bathrooms, and kitchens, where moisture levels are high, applying an epoxy resin coating can be an effective preventative measure. By sealing surfaces and preventing moisture from entering the material, epoxy ensures that mold and mildew do not have the opportunity to take root. This application is particularly beneficial for protecting wood and concrete surfaces in damp environments, where traditional coatings might fail.

How Brampton Can Help

At Brampton, we understand the importance of high-quality, cost-effective materials in construction. With our extensive experience in developing adhesives, epoxy products, and grip solvents, we are committed to helping the construction industry meet its demands for strength, durability, and sustainability. Whether you need epoxy for structural bonding, flooring, coatings, or repairs, we offer products that ensure reliable performance across various applications.

Brampton’s products are manufactured with a focus on safety and quality, providing solutions that make construction projects more efficient and effective. Our epoxy solutions are engineered to meet the diverse needs of the construction industry, offering exceptional adhesion, durability, and resistance to harsh conditions.

By choosing Brampton, you can rely on a family-owned company with decades of expertise in delivering top-notch products for the construction sector, like epoxy glue, and more.