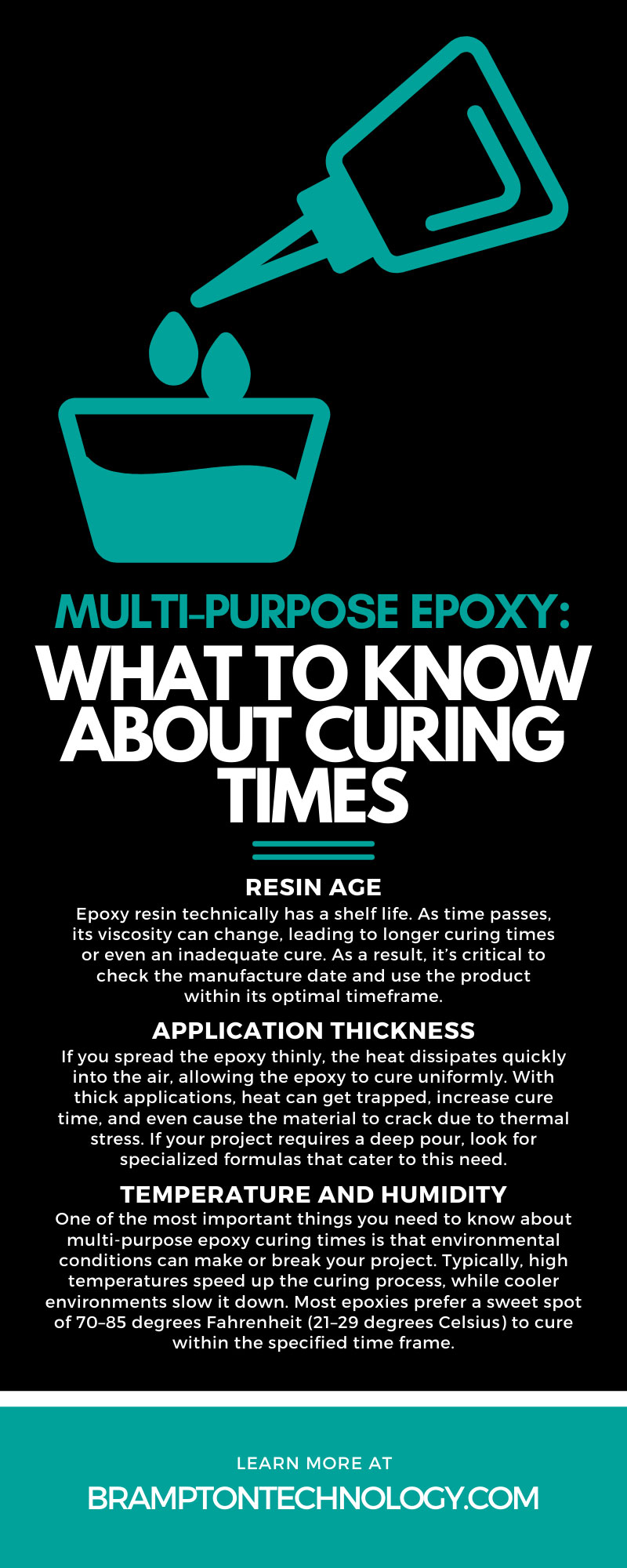

Multi-Purpose Epoxy: What To Know About Curing Times

Epoxy resin is a DIY enthusiast’s dream adhesive; it provides versatility and durability for a wide range of projects. Whether you’re sealing a garage floor, creating custom countertops, or embedding keepsakes in clear castings, an all-purpose epoxy can help you get the job done.

Knowing how long your epoxy takes to set can be the difference between a masterpiece and a mess. If you’re ready to become an epoxy expert, take a deep dive into everything you need to know about multi-purpose epoxy curing times.

The Science Behind Epoxy Curing

At the core of the epoxy curing process lies an interesting chemical reaction known as polymerization. This is where the magic happens! The liquid resin and hardener transform into a solid. When these two components come together, they trigger a cross-linking reaction that progressively strengthens the mixture.

Temperature, humidity, and the ratio of resin to hardener all participate in this molecular dance. It’s a bit like baking a cake: mix the ingredients correctly, set the right temperature, and you’ll have a beautiful outcome. However, missteps could lead to a less-than-desirable result.

Proper Mixing and Surface Preparation

Before pouring the epoxy, you must prepare your surface. The area receiving the epoxy should be clean, dry, and free of oils or debris. Even one particle of dust can sabotage the integrity of your project.

To sidestep issues, thoroughly clean the surface with isopropyl alcohol and allow it to dry completely. Moreover, roughening smooth surfaces with a bit of sanding can create a more adhesive-friendly environment for the epoxy. Meticulous prep work will reflect in the shining, flawless finish of your fully cured product.

Factors That Affect Curing Time

Resin Age

Epoxy resin technically has a shelf life. As time passes, its viscosity can change, leading to longer curing times or even an inadequate cure. As a result, it’s critical to check the manufacture date and use the product within its optimal timeframe.

As resin ages, it may become thicker, which can throw off the delicate balance with the hardener and prolong the curing period. For the best results, always use fresh epoxy and store unused portions in a cool, dry place to preserve their reactive properties.

Application Thickness

The thickness of your epoxy application is another important factor that dramatically affects its curing time. Thick layers generally take longer to cure than thinner ones. As epoxy cures, it generates heat—a process known as exothermic reaction.

If you spread the epoxy thinly, the heat dissipates quickly into the air, allowing the epoxy to cure uniformly. With thick applications, heat can get trapped, increase cure time, and even cause the material to crack due to thermal stress. If your project requires a deep pour, look for specialized formulas that cater to this need. You could also consider layering multiple thin pours, allowing each to cure fully before adding the next.

Temperature and Humidity

One of the most important things you need to know about multi-purpose epoxy curing times is that environmental conditions can make or break your project. Typically, high temperatures speed up the curing process, while cooler environments slow it down. Most epoxies prefer a sweet spot of 70–85 degrees Fahrenheit (21–29 degrees Celsius) to cure within the specified time frame.

Low temperatures result in sluggish cures, leaving you with a tacky finish. Conversely, working in a hot environment can expedite the curing process, giving you less time to work with the epoxy before it hardens.

You also have to consider humidity, as high moisture in the air can introduce unwelcome cloudiness or imperfections in your finished product. Maintaining a controlled environment or adjusting your project timeline to align with environmental conditions can help you achieve a rock-solid, crystal-clear result.

Mixing Ratio and Hardener Cure Speed

Adhering to the precise mixing ratio recommended by the manufacturer’s instructions can guarantee successful curing. This ratio is the proportion of resin to hardener you must mix, and it varies per epoxy product. You can’t eyeball quantities when mixing epoxy and hardener. Even slight deviations can result in a sticky mess or a brittle final product. The measuring cups in your resin kit help you achieve accurate pours, so use them!

Your choice of hardener is also important. This product comes in various cure speeds—fast, medium, or slow. A fast hardener is great when you’re on a tight schedule, but it can be unforgiving if you’re new to the process—it leaves little room for error. On the other hand, a slow-curing hardener affords more time for application, making it a wise pick for complex, intricate projects or for those mastering their epoxy pouring skills.

Type of Resin

Choosing the appropriate type of resin for your project is just as important as any other step. Manufacturers formulate resin with various properties to suit different applications, from UV resistance for outdoor projects to food-safe ratings for kitchenware. Some resins have a fluid-like consistency, which makes them ideal for detailed projects. Others are thicker and better suited for creating doming effects on surfaces.

When selecting epoxy, consider the end-use and desired aesthetics of your project. For example, quick-repair formulas usually cure faster than those intended for artwork or tabletops. Curing too quickly can lead to trapped air bubbles and an uneven finish, while a prolonged curing period may result in dust or debris embedding into your project’s surface.

Exposure to Sunlight

Ultraviolet (UV) light can cause discoloration and weaken the structural integrity of the epoxy over time, leading to yellowing or brittleness. If you’re working on a project that will get frequent exposure to sunlight, choose a formulation that includes UV inhibitors or stabilizers. These special additives can extend the lifespan of your project by providing resistance to sunlight. These protective qualities can make a remarkable difference in preserving the clarity and beauty of your handiwork against time and the elements.

Meticulous attention to these details transforms a simple mixture of resin and hardener into a magnificent and durable creation. Project perfection relies on you choosing a quality product. At Brampton Technology, our all-purpose epoxy adhesive comes in a range of durable, weather-resistant formulations so you can tackle any project.